03-03-2021

One thing for sure the three gearbox off a Motom is not spectacular.

It would be nice if we can create a close three gearbox for a Motom.

Together with Fabio a Italian friend and Motom enthusiast, we try to create a close gearbox.

Lets see how far we come.

First, you need to remove the two pressed gears.

I tried to heat them up and press with the rotating Centerpoint.

But it is too tight.

Then used a hydraulic press and that worked ok.

Roughly removed the first gear.

Then I used the grinder, so close a possible.

Then I clamped the Dremel.

And grind roughly to 0,1mm larger than the shaft.

In action.

Then for the fine grinding I used a fine rotating sanding tool.

For the last 0,01's

In action

Looking good.

Gears mount on tight.

The idea.

11-03-2021

Until now everything went well, the next challenge is to enlarge the lock key so the new first gear is locked.

Thought about many thinks, but the shaft is hardened steel so at least I should grind the hard top off if I wanted to use a 4mm mill.

Then I thought perhaps I could grind the whole thing with a 4mm grind stone.

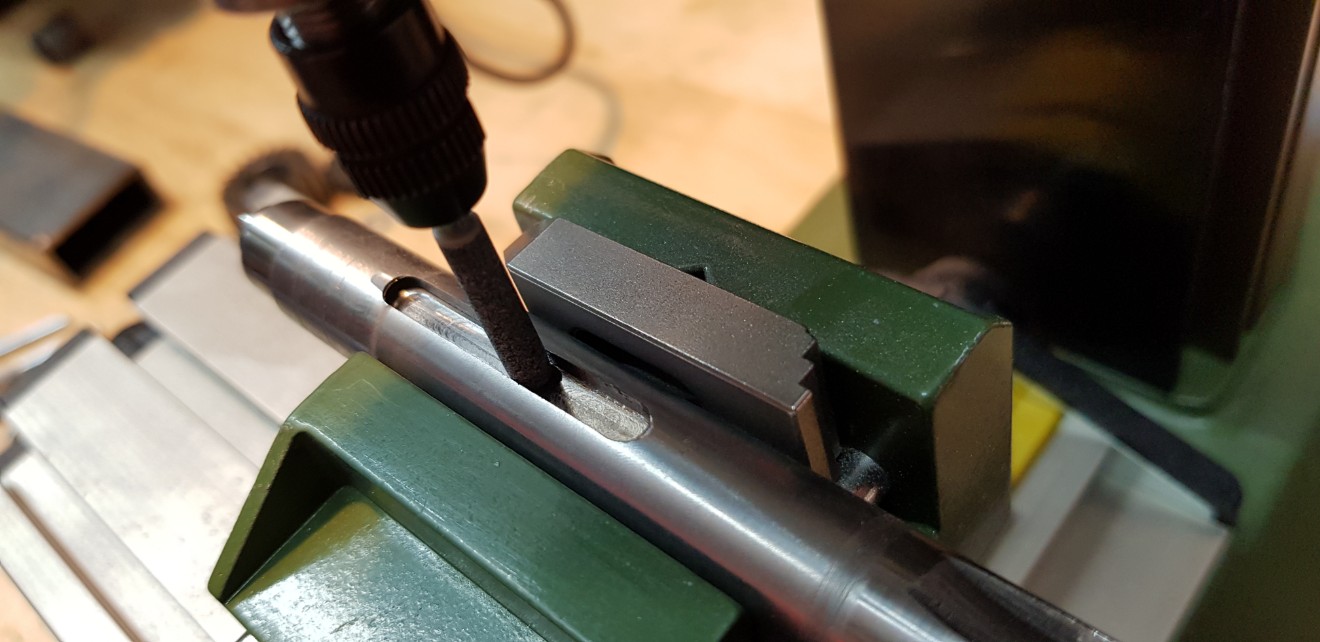

Of course I need to hold it steady so perhaps a tiny mill with a high rotation is an option.

It seems the Proxxon MF70 spins at 20.000 rpm and can use a 4mm grind stone.

So lets try it.

The idea.

The Setup.

And here the first couple of runs.

You can see clearly the bottom rounds off quite easily.

Slowly it takes shape.

The deeper I went the easier it goes.

Also the grind stone was holding better.

In action.

And after many runs and six 4mm grindstones it was ok.

This should work.

4mm grinds stones, you can see they round off at the bottom.

14-03-2021

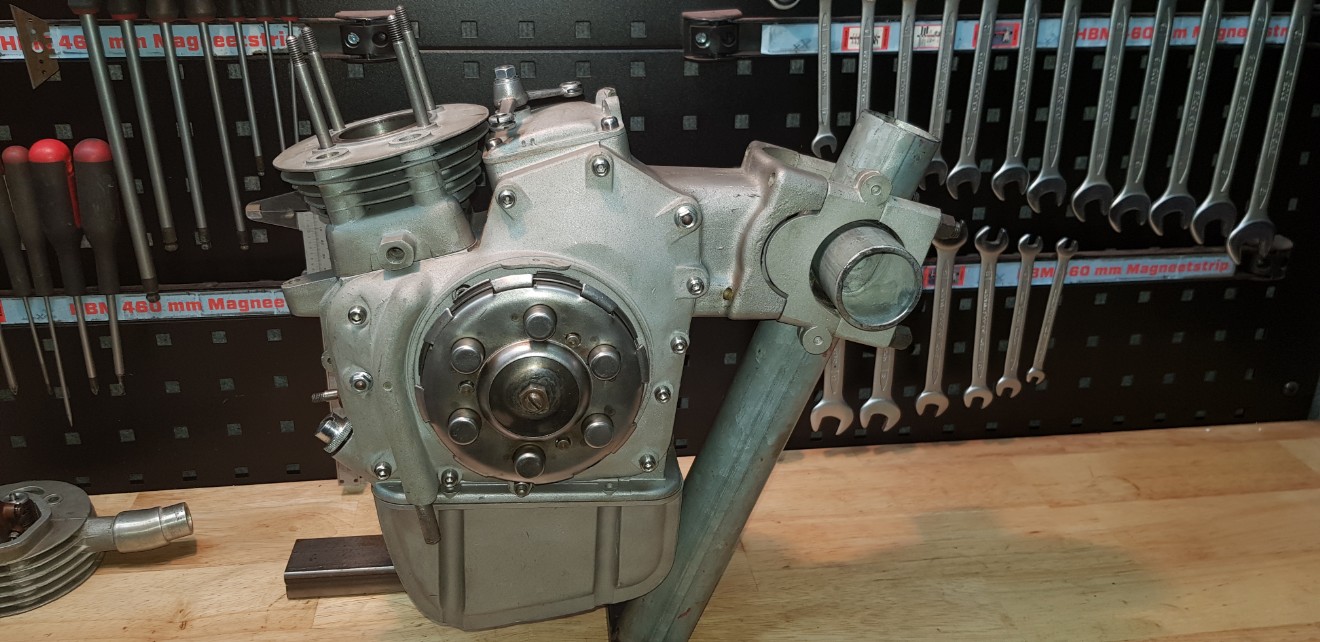

Now it was time to mount everything back in an Engine.

I'm planning to use a Zappa engine for my Road going Motom so it will be easier to play with the ignition timing.

And it will stand out from other motom's do its separate ignition point.

Let's get started.....

Cut two keys to get the whole length.

The first impression it is tight, but still runs free

With my first measurements this should be good. One 3,9mm plate

Looking all good.

Also made sure it was shifting nice, before I mount it all.

Put everything on time (also the points at the bottom)

Made a tiny modification, so the clutch seal was running free.

Well and here she is, all good I thought.......

Sadly, I pulled the clutch, and a small "clack" sound was noticeable.

Turns out the clutch bearing moved into its place a bit more.

Need to open here up again and give the clutch shaft a thicker ring so it will lock the gears

This time we go for 4,6mm

Larger rings (original)

Hope they won't hit the other gear.

Still running free, but its close

Ready again, next step clinder and head

Need to solve some problems in order to get my test engine ready.

1) Front sprocket turns to be difficult to get hold off and i want a 17 front.

2) Cylinder piston 40,2 does not fit combustion chamber.

Front sprocket is really hard,.

Thought I could cut it like this. But this plan does not work.

Plan B is to weld it on the 12T Zappa sprocket

Machined the sprocket.

Shortened the spacer

Done

Machined the 12T

Untill this.

Mounted it for welding

Welded, and start machining.

Not that bad.

It still fits.

On the same place as original.

Looking at all the parts I bought, found a good 15/15 head.

Found some valves and, clean them.

It's a strange head, it misses the counter hole in the rocker arm.

Drilled a hole.

Fount a 39,3 cilinder and piston